In the food and beverage industry, every piece of equipment that comes into contact with consumable products must meet strict safety and hygiene standards.

Among the most important are food grade hoses. These flexible connectors are essential for safely transferring liquids, semi solids or gases without contaminating the final product.

In this guide, we’ll explore the key food grade hose safety standards and offer practical hygienic guidance to help you choose and maintain the right solution for your operation.

What Is A Food Grade Hose?

A food grade hose is specifically designed for the safe transfer of food, beverages or pharmaceutical materials. Unlike standard industrial hoses, food grade hoses are made from materials that don’t leach toxins, aftertaste or odours into the products they’re transferring.

Typical materials include PVC, silicone, EPDM rubber, nitrile and PTFE (Teflon); all chosen for their smooth, non-porous inner linings and resistance to temperature, pressure and cleaning chemicals.

Food grade hoses are commonly used in applications such as:

- Dairy and milk processing

- Brewery and distillery production

- Beverage bottling and soft drink manufacturing

- Food production and packaging

- Pharmaceutical and cosmetic processes

The right hose doesn't just ensure efficiency, but also compliance with hygiene and safety regulations.

Understanding Food Grade Hose Safety Standards

When it comes to food grade hose safety standards compliance isn’t optional, it’s a legal and ethical requirement to protect consumers from contamination. These standards cover everything from the composition of the hose materials to their resistance to bacteria and ease of cleaning.

Here are the key standards to be aware of:

EU Regulation 10/2011

For operations within the UK and EU, this regulation defines which plastic materials can safely contact food and how they should be tested for migration of substances.

EC 1935/2004 and BfR Recommendations

These European frameworks require that any materials used in food processing do not transfer their components into food in harmful quantities, and that they maintain product integrity.

WRAS Approval (Water Regulations Advisory Scheme)

In applications involving potable water, hoses must also meet WRAS standards to ensure water remains safe and uncontaminated.

FDA Compliance

In the US the FDA regulates materials that come into contact with food under CFR Title 21. Hoses labelled “FDA compliant” or “FDA approved” are made from materials tested and certified to be safe for food contact.

Collectively, these frameworks ensure that food grade hoses are non-toxic, odourless, tasteless and easy to clean, protecting both the end product and the consumer.

Hygienic Hose Guidance and Best Practices

Even the best food grade hoses can compromise hygiene if they aren’t installed, cleaned or maintained correctly. It’s important you ensure your equipment performs safely and reliably.

Cleaning and Sterilisation

Regular cleaning prevents the build-up of residue and bacteria. Use approved cleaning solutions and sanitisation methods compatible with the hose materials; such as steam cleaning for high temperature hoses or clean-in-place systems for process lines.

Correct Storage

After cleaning, hoses should be hung vertically to drain fully and stored in a clean, dry environment away from direct sunlight. Avoid coiling hoses too tightly as this can cause kinks or internal damage.

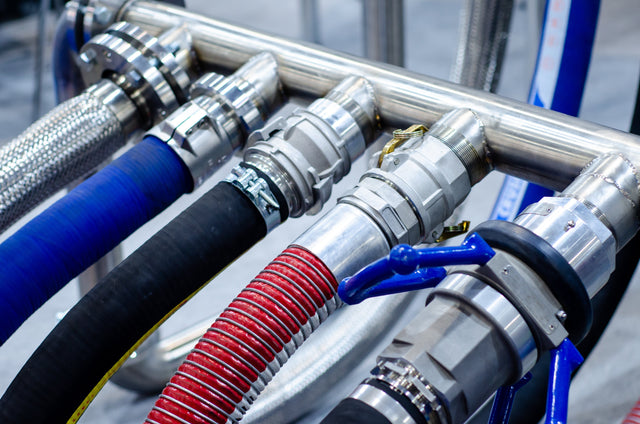

Use the Right Fittings

Incorrect or incompatible fittings can create small gaps where bacteria can accumulate. Always use hygienic stainless-steel couplings and gaskets designed for food contact.

Regular Inspections

Inspect hoses frequently for wear, cracks, soft spots or discoloration. Any signs of degradation could indicate contamination risks and should prompt immediate replacement.

Replacement Intervals

Even with proper care, food grade hoses have a limited lifespan. Manufacturers typically recommend replacing them every 6 to 12 months depending on the usage intensity and cleaning frequency. Keeping maintenance logs helps ensure timely replacements.

Colour Coding and Labelling

Many facilities use a color coded system to separate hoses used for different food products (dairy vs juice) or processes (raw vs cooked). This simple step significantly reduces the risk of cross contamination.

Choosing the Right Food Grade Hose

Selecting the right hose depends on several operational factors:

- Identify the product type: is it liquid, semi solid or gas?

- Check temperature and pressure ratings: choose materials that can handle your operating environment.

- Assess chemical compatibility: ensure the hose won’t degrade when exposed to cleaning agents or ingredients.

- Confirm certification: look for hoses that meet regulatory requirements.

- Prioritise flexibility and durability: a good food grade hose should handle frequent movement and cleaning without cracking or kinking.

Working with a specialist supplier ensures you get tailored advice and hoses that meet every applicable regulation.

Common Mistakes to Avoid

Even well intentioned operators can make costly errors when managing food grade hoses. Avoid these common mistakes:

- Using non certified hoses in food processing areas

- Exceeding temperature or pressure limits

- Skipping or shortening cleaning cycles

- Improperly storing hoses after use

- Neglecting to replace hoses when they show signs of wear

- Failing to maintain records or certification documents for inspections

By taking a proactive approach to maintenance and compliance, businesses can significantly reduce downtime and improve product safety.

Maintaining food safety is a shared responsibility, and choosing the right hose is a vital part of that process.

By following recognised food grade hose safety standards, understanding regulation-approved hose requirements and adhering to proper hygienic hose guidance, you can ensure every product that passes through your line remains safe, pure and high quality.

For expert advice or to explore our full range of compliant hoses and fittings, get in touch with our team.